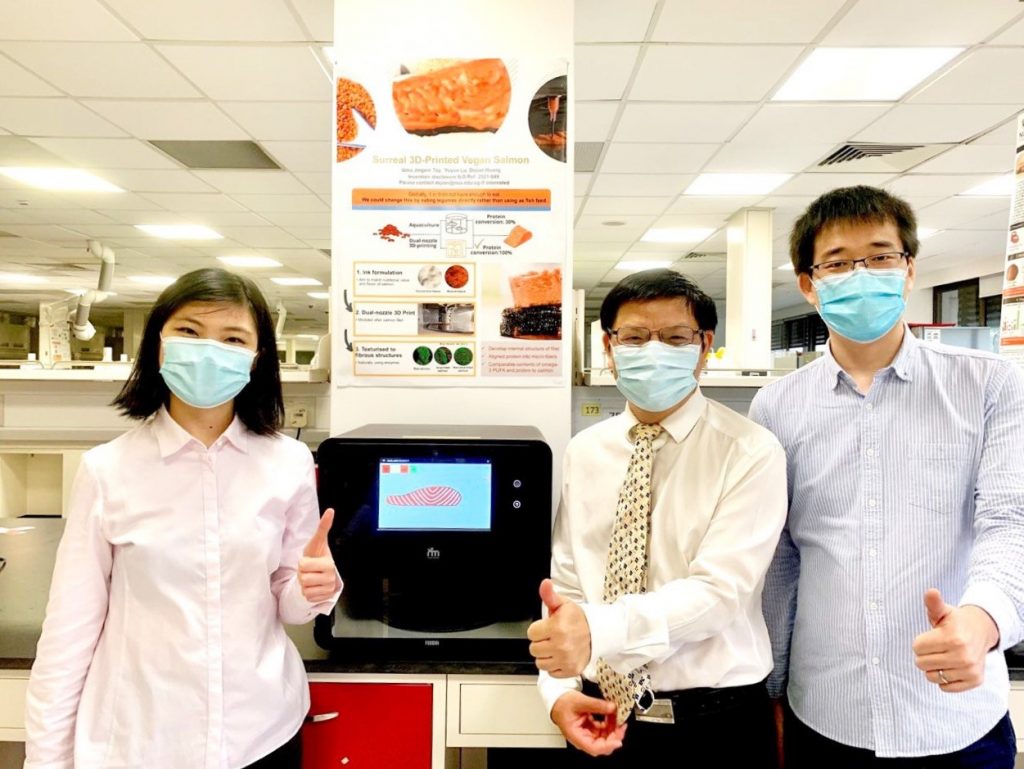

Tay Jingxin Uma, Winner of the Outstanding Undergraduate Researcher Prize for Academic Year 2020/21

FST is proud to announce that Tay Jingxin Uma has been awarded the Outstanding Undergraduate Researcher Prize for Academic Year 2020/21. The Outstanding Undergraduate Researcher Prize (OURP) is a university-wide competition to encourage research and to recognise the best undergraduate researchers in NUS. Uma will be graduating this month, and continuing with her PhD studies in NUS Food Science and Technology to further her research on alternative proteins.

Uma’s Testimonial

Words cannot express how honored and touched I am to be awarded the Outstanding Undergraduate Researcher Prize (OURP). I am grateful to be part of NUS Faculty of Science, especially my department (Food Science and Technology (FST)), for exposing me to a strong research infrastructure and culture. Although I simply had endless questions, the FST lecturers were ever patient in guiding me towards finding answers towards them. They have developed in me a curiosity and confidence towards the potential that food research has in addressing my life-long ambition of developing plant and microbial-based mimics of livestock-derived products.

I am grateful to my supervisor (Associate Professor Huang Dejian) and co-supervisor (Dr Lu Yuyun) for the opportunity to explore the potential of dual-nozzle 3D printing in rational design and texturization of meat-like structures from pulse proteins. To maximize the capability of 3D printing, we decided on salmon as our mimic target. Salmon fillet has an intricate structure comprising of alternating thin layers of myomere (muscle) and myosepta (connective) tissues. Amongst the various challenges, the greatest to me was time management. Intensive sample analysis coupled with sensory evaluations nonetheless revealed that, even amongst the most promising additives and processing technologies, many failed to confer pulse proteins the functionalities needed. I am ever grateful to Prof Huang for guiding me in developing techniques to walk around the insurmountable obstacles, rather than fruitlessly attempt to scale these rocks. Persevering through these challenges made every small progress all the more rewarding. To have made the resemblance of our mimic this close to salmon surpassed what I could ever envision. I am ever grateful to my supervisors for their trampoline leadership; giving me the resources I needed to soar to new heights while providing a safety net through multiple consultations.

Fundamental to the success I had in developing the salmon mimic is my UROPS supervisor (Professor Zhou Weibiao) and co-supervisor (Andrea Koo). My UROPS supervisors inculcated in me the mentality and skills needed to perform a research project. The foundation they gave me boosted my efficiency in innovating the salmon mimic.

To all my lab friends, I appreciate you for your company, keeping an eye on my experiments and generous sharing of your expertise in operating equipment. In particular, Amelia, Chun Hong, Xinli, Xinlu, Xingyi, Yinglan and Yuzhu. To Ms Jiang Xiaohui, Ms Lee Chooi Lan, Ms Lew Huey Lee, Shermaine, Hanny and Jiaxuan of FST department and Ms Lee Shu Ying of Medicine Confocal Microscopy Unit thank you for the technical training. To my family, thank you for your support and care all these years.

I am grateful to my PhD supervisors, Dr Prakash Arumugam, Prof Huang and Prof Zhou, for giving me the opportunity to continue my exploration of the unchartered waters of alternative proteins research.

About the project

With strong support from my supervisors, I successfully developed a 3D-printed plant-based salmon fillet mimic. Pulse protein-based emulsions were used as inks to simulate the myosepta and myomere tissues of salmon fillet. The myomere, which is the orange-red muscular tissue, is simulated as an emulsion-filled protein gel. Its colour was conferred naturally by red lentil protein and supplemented with high-intensity ultrasound extracted astaxanthin (the principal colouring pigment in salmon). Protein isolation from red lentil was optimized to address solubility issues arising from commercial protein extraction techniques. Whereas the myosepta, being the white-coloured connective tissue, was simulated as a yellow pea protein-stabilised emulsion. High pressure homogenization was performed to enhance printability. Incorporating these simulants in our 3D printing methodology not only matched salmon macronutrient content (including 𝜔-3 polyunsaturated fatty acid), but also served to enhance resemblance macro- and micro-structurally. Besides aligning the inks into the characteristic internal structure of salmon fillet, 3D printing aligned constituent protein aggregates as reflected from confocal laser scanning microscopy coupled with scanning electron microscopy. Subsequent incubation of the printed mimic at 55 °C served to induce transglutaminase-catalysed cross-linking of proteins into fibrous network which transformed the mimic from a printable paste-like form into a firm structure. In the myomere simulant, widths of protein microfibers had good similarity to salmon myofiber (p < 0.05). Achieving anisotropy up to myofiber scale represents an advancement relative to conventional protein structuring approaches such as extrusion. Whereas, in the myosepta simulant, fibrous protein network coupled with comparable oil droplet size distribution to myosepta, reflects its promising potential to simulate fat release behaviour of myosepta. My work demonstrated that 3D printing followed by protein texturization is a promising approach to cost-effectively convert plant-based ingredients into high-resolution nutritious seafood mimics. These mimics can be further personalized according to taste and dietary preference of consumers.